We have good news and bad news.

Part one of the bad news is that our knee motor broke. Our knee system uses a worm gear and regular gear; as we mentioned in the last entry, the regular gear is made of plastic and got stripped. In the meantime, we’ve ordered replacement plastic gears so that we can continue doing testing and integration of the knee system. We still haven’t found a metal gear that can perfectly replace our plastic. We are considering the following options:

– replacing the knee gearbox with a different gearing system/motor

– seeing if we can find a company that can custom make a metal gear for us

– seeing if we can make a gear ourselves on campus (via a metal shop)

Part two of bad news is that our ankle servo isn’t working. We are still investigating why it doesn’t work. This is especially troublesome because we have a presentation/demo later this week…

The good news is that we’ve made progress on the armband.

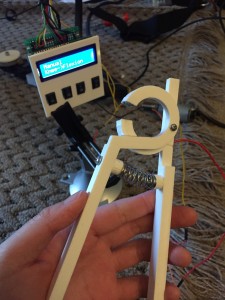

Previously, the contacts didn’t perfect overlap and the extensions on handle for the springs were too small. These were fixed, and the handle was extended (length-wise) so that it fits the user’s hands better.

This is the first iteration for the armband cover. The LCD slot is a great fit while the button slots are a little too wide. There’s a lot of extra space on the bottom where the vector board for the LCD isn’t covered. The side view photo also shows that there’s extra space between the (bottom of the) LCD screen and the buttons. For the next iteration, the plan is to fix the button slots and to rearrange the slots. Once the cover is complete, we plan to make a small box to enclose the hardware. Then the box will be attached to a strap (velcro or a modified iPod strap) so that the armband unit is wearable by the user.

This is a updated version (see the first version) of the toggle handle in action. The toggle has been connected to the buttons, which are connected to the RPI. When the handle “closes” (the contacts touch each other), the signal is relayed to the RPI (control system), which then drives motor movement. In this case, we see the worm gear (a part of the knee system) moving. Because of the aforementioned issues/bad news, you don’t see the worm gear drive the knee portion of the leg brace.

This is one of the fiberglass pieces. It has been sanded (though it’s still a little rough/you can see some individual fibers) and painted black.