We thought that we could use existing parts to make the kind of handle our user wanted (their description for the kind of handle they wanted was something like a fire extinguisher handle, i.e., could be worked in a squeezing fashion). However, we weren’t able to, so we decided to design and 3D print a handle instead.

I (Sarah) made the handle in SolidWorks and initially modeled it off a bike brake. A rim brake applies friction to a tire rim to slow/stop a bike. We decided to get rid of the tire and have the brake work as a contact switch instead.

Bike brake reference

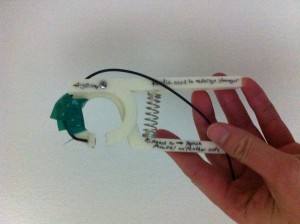

A bike brake includes a lever, Boden cable, and the brake itself. Chase suggested combining the lever and brake (or contact switch in this case) so that we wouldn’t have to use Boden cable and to decrease the number of parts we have to make/print. Therefore, what we ended up with was something like this:

As you can see, the handle is made up of two separate pieces that are connected/held together with a screw and bolt. We have a spring to keep the contacts apart and to help with the squeeze motion (like wirecutters, which require force to bring the cutters together to cut the wire). A wire from one of the contacts was taped to the handle to secure the wire, but this is for now (i.e., the final product won’t look like this).

We will be making adjustments as the grips are a little short for the user’s handle. As the control team evaluated the handle, we realized that the grips should probably be thicker/sturdier (the cross section is 0.3″x0.3″). I’m going to redesign the grips so that I can slide and then glue PVC onto them.

The following is a video of the handle “in action”: